How Extruded Aluminum Is Made – Step by Step Inside the Press

26 September 2025How Does Aluminum Extrusion Work? — Overview

At its core, how aluminum extrusion works is straightforward: a solid aluminum billet is heated, placed into a container, and forced through a specially shaped die by a ram. The metal flows through the die and emerges as a continuous profile with the die’s cross-section. What looks simple hides many controlled variables: alloy selection, billet temperature, die design, ram speed, press type, quench method and downstream heat treatment all affect final properties.

Step-by-Step: How Aluminum Extrusion Is Made (Inside the Press)

Step 1 — Alloy selection & billet production

- Choose an alloy based on strength, corrosion resistance and formability (e.g., common families: 1xxx, 3xxx, 5xxx, 6xxx).

- Billets are cast (direct chill casting is common) and often homogenized (heat-soaked) to reduce segregation and improve flow.

Step 2 — Billet inspection & preparation

- Cut billets to the pressable length.

- Inspect for cracks, porosity and correct diameter.

- Billets may be preheated to a target temperature to improve flow — typical ranges vary by alloy (commonly a few hundred °C) and are tightly controlled to avoid surface defects or over-softening.

Step 3 — Die design & tooling setup

- Toolmakers produce a die (and mandrel for hollow shapes) to the required cross-section. Dies are typically made from tool steels able to withstand high pressure and temperature.

- Die design includes details for material flow, radii, wall thickness limits and any features that ease ejection and finishing.

- Dies are fitted to a die carrier and aligned in the press.

Step 4 — Lubrication and dummy block

- A lubricant is applied to reduce friction between the billet, container and die. It also helps heat control and surface finish.

- A dummy block (pusher block) sits between the ram and the billet to protect the ram and ensure even force distribution.

Step 5 — Loading the billet into the press (inside the container)

- The preheated billet is loaded into the container. The container guides material to the die and contains pressure.

- The ram starts pushing (or, in indirect extrusion, the die moves) and plastic deformation begins. This is literally the moment inside the press where the billet begins to flow.

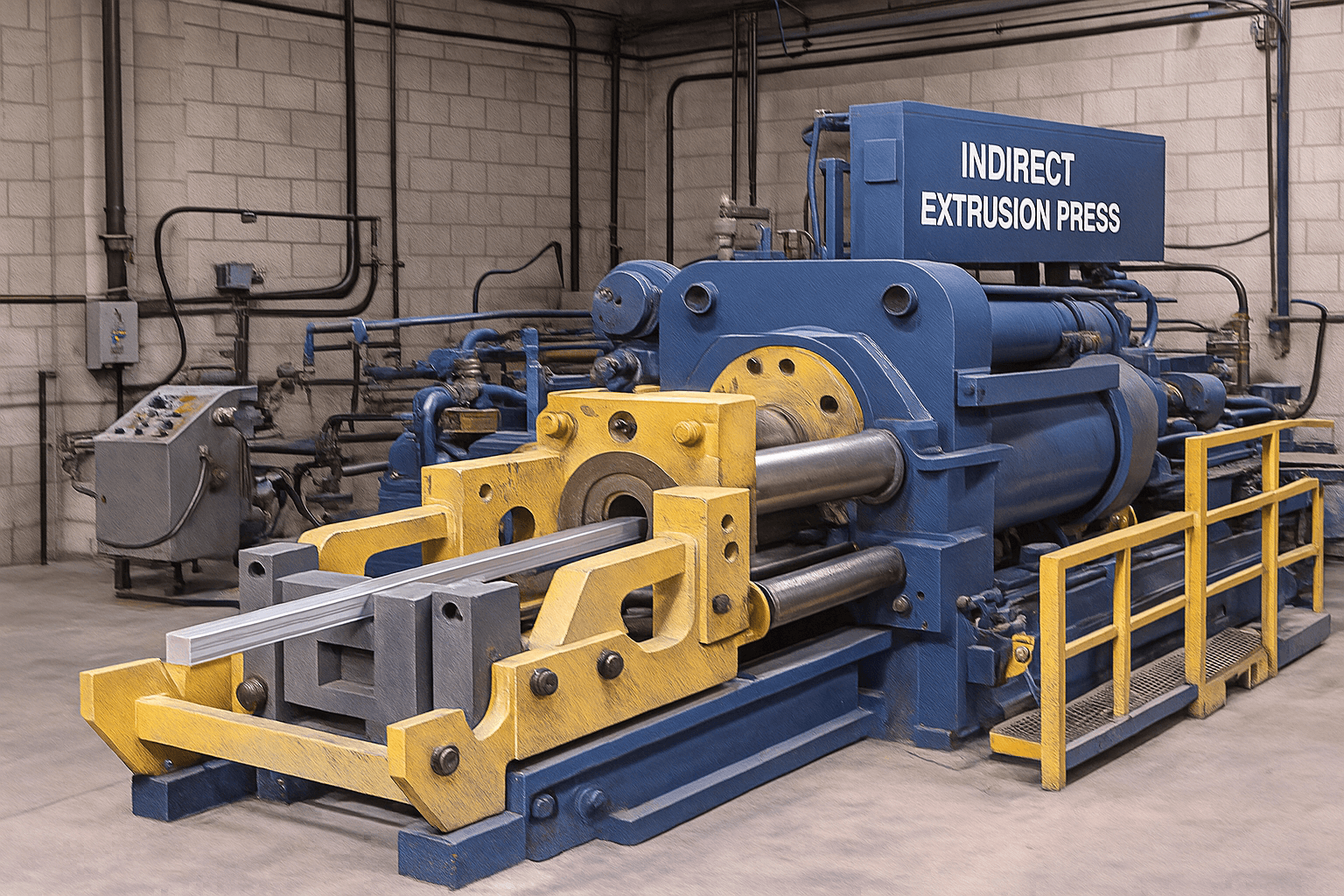

Direct vs. indirect (backward) vs. hydrostatic

- Direct (forward) extrusion: Ram pushes billet through a stationary die at the container end. Friction between billet and container is significant.

- Indirect extrusion: The die is attached to the ram and moves into the billet; the container remains stationary. Friction is lower, and required press tonnage can be less.

- Hydrostatic extrusion: Billet is surrounded by a pressurized fluid — used for difficult alloys or very high extrusion ratios.

Step 6 — Material flow through the die

- Metal flows through the die orifice, adopting the die cross-section. For complex or hollow profiles, mandrels and internal supports guide metal around voids.

- Extrusion speed and ram pressure are monitored — too fast or too cold causes tearing or surface defects; too slow or too hot raises costs and can lower mechanical properties.

Step 7 — Exit, cooling and quench

- As the profile exits the die, it’s supported on pullers or runout tables.

- Profiles are often quenched immediately (air or water) to control microstructure and mechanical properties. Quench type and timing affect final strength and surface condition.

Step 8 — Cutting and stretch-straightening

- Long extrusions are cut to manageable lengths.

- A stretcher applies a controlled tensile force to remove residual stresses and straighten the profile — essential for dimensional accuracy.

Step 9 — Heat treatment & aging

- Depending on the alloy and specification, parts may undergo heat treatments: e.g., solution heat treat, quench and artificial aging (T-temper processes), or just aging (T5) to reach target mechanical properties.

Step 10 — Secondary operations & finishing

- Secondary machining, punching, drilling, joining or anodizing/powder coating occur after extrusion.

- Surface finishing (anodize, paint, mechanical polishing) is chosen based on appearance, corrosion resistance and downstream requirements.

Step 11 — Quality control & testing

- Dimensional inspection (CMM, gauges), mechanical testing (tensile, hardness), surface checks and metallurgical analysis ensure the extrusion meets spec.

- Non-destructive tests and sampling plans are used for critical components.

Step 12 — Packaging & recycling

- Finished extrusions are packaged to prevent damage. Offcuts and scrap are routinely recycled — aluminum is highly recyclable with minimal quality loss.

Key Inside-the-Press Terms Engineers & Buyers Should Know

- Billet: the cylindrical feedstock.

- Die: the tool that shapes the cross-section.

- Container: holds the billet during extrusion.

- Dummy block: buffer between ram and billet.

- Mandrel: forms internal cavities for hollow profiles.

- Quench: rapid cooling to control microstructure.

- Stretching: straightening and relieving residual stress.

- T-temp: common temper notations (T5, T6) for heat treatment/aging.

Practical design & procurement tips

- Design for extrudability: avoid extreme thin walls and abrupt section changes. Use generous radii and consider hollow sections to lower weight.

- Specify alloy and temper: don’t rely on the extruder to choose unless you want them to. State mechanical/property targets.

- Think downstream: include tolerances and finish (anodize vs powder coat) early. Secondary machining should be minimized by thoughtful profile design.

- Ask about tooling costs & lead time: custom dies are an upfront cost; reusing dies reduces lifecycle cost.

Buyer Checklist (quick)

- Alloy & temper specified?

- Cross-section manufacturable? (wall thickness, radii)

- Required tolerances & straightness specified?

- Surface finish and post-treatment specified?

- Sample/first-article inspection plan?

- Tooling ownership/return policy clarified?

Conclusion — How Aluminum Extrusion Is Made & Why It Matters

Understanding how aluminum extrusion is made and what happens inside the press helps engineers create better parts and helps buyers set clearer specs. Control points — billet prep, die design, press type, extrusion speed, quench and heat treatment — determine final form, performance and cost. Communicate these early with your supplier to avoid surprises and get the most value from extrusion.

Images to include (suggested):

- Inside a horizontal extrusion press: billet in container, ram and die (alt: “inside extrusion press showing billet, container and ram”).

- Heated billets in a furnace (alt: “aluminum billets in preheat furnace”).

- Extrusion exiting die and quench line (alt: “extruded profile exiting die being quenched”).

- Stretcher pulling and straightening profiles (alt: “stretch straightening aluminum extrusion”).